MFC System of anhydrite screeds

- Thermal conductivity

- Lifetime

- Flatness

Anhydrite screeds are designed for cast levelling layers especially in residential, civil and industrial buildings with an operating load of up to 7.5 kN/m2. Anhydrite cast screeds are also very suitable for underfloor heating systems - the screed structure is homogeneous throughout its thickness without further compaction (good thermal conductivity), it is not necessary to dilute individual heating circuits. Floors from anhydrite screeds are made with a flatness of ± 2 mm/m and do not require additional levelling mortar for laying the final surface layer here

Anhydrite screeds: MFC Anhydrit 020 (025 a 030) is a fresh self-levelling screed mixture based on calcium sulphate (anhydrite), filler, admixtures, and water. During the curing of the screed, a crystal structure is created; relatively large and compact crystals interconnect with their whole area, creating only a minimum quantity of hollow gaps. Thanks to this structure anhydrite screeds achieve high strength here.

Benefits of delivery with the TransMix/Bremat application semitrailer

TransMix/Bremat mixing and mobile set is mainly for production of liquid coating at the construction site. It is equipped with material storage tanks, mixing set and helical pump. The fresh coating is transported via mentioned equipment directly to intended location.

Main benefits:

- fully automated production with exact batch processing takes care of steady coating quality

- TransMix stays at the site for the time really needed to install coating

- coating production and transportation is continuous, there is neither worker nor machine idle time

- the quantity needed for particular surface is produced only - minimalization of additional cost

- immediate consumption supervision on the spot

- minimal requirements to the construction site equipment

We cover almost whole Czech and Slovak Republic...

We cover map with four points of alert: Tišnov u Brna, Praha - Modletice, Hradec Králové, and Senec u Bratislavy!

Quantity is no challenge to us...

Currently we already have seven fully equipped sets, with daily output reaching more than 210 m3!

|

|

|

|

System benefits:

- Productivity (ca 1,000 m2 of floor areas per day)

- Operational load to 7.5 kN/m2

- Good thermal conductivity, suitable for underfloor heating

- Low coefficient of thermal expansion

- High degree of flatness ± 2 mm/m

- Wear layer in 24 hours, 50% of the load after 5 days

- Long lifetime - min. 10 years

- Almost without the need for dilatation

Disadvantages:

- Not suitable for permanently wet areas

- Drying time before covering (approx. 28 days)

Base compositions of anhydrite screeds

|

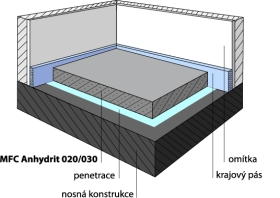

BONDED SCREEDS Bonded screeds are usually responsible for balance and prepare the uneven surface of the carrier substrate for subsequent use. The screeds must be bonded to the substrate on the entire surface firmly and without interruption. This way you can ensure the transmission of the action potential power directly to the base layer. Layer thickness from 10 mm. |

|

|

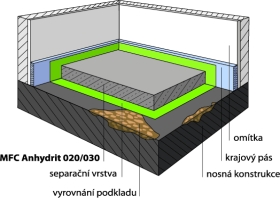

SCREED ON THE SEPARATION LAYER

|

|

|

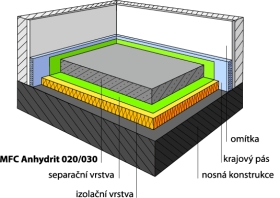

SCREED ON THE INSULATION LAYER

Increased sound insulation requirements, especially in residential construction, require a floor structure with a coating on the insulation layer. It is with these floor structures that the minimum thickness of the screed is dependent on the expected operating load and also on the stability of the insulation layer. Layer thickness from 30 mm.

|

|

|

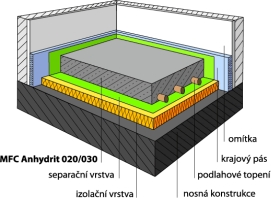

HEATING SCREED

|