MFC "wet to dry" (self-levelling screeds)

- High productivity

- High rolling resistance

- Color options

- The surface is walkable after 3 hours, mobile after 24 hours

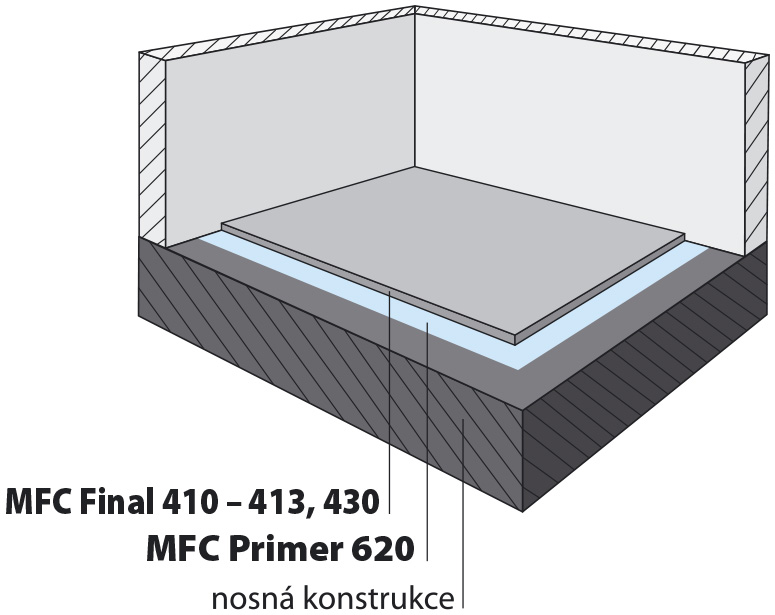

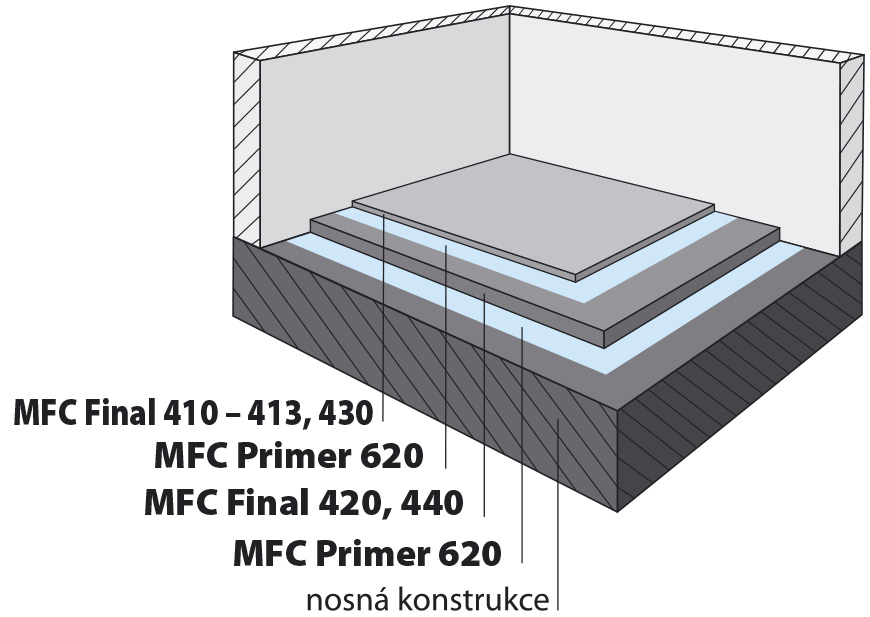

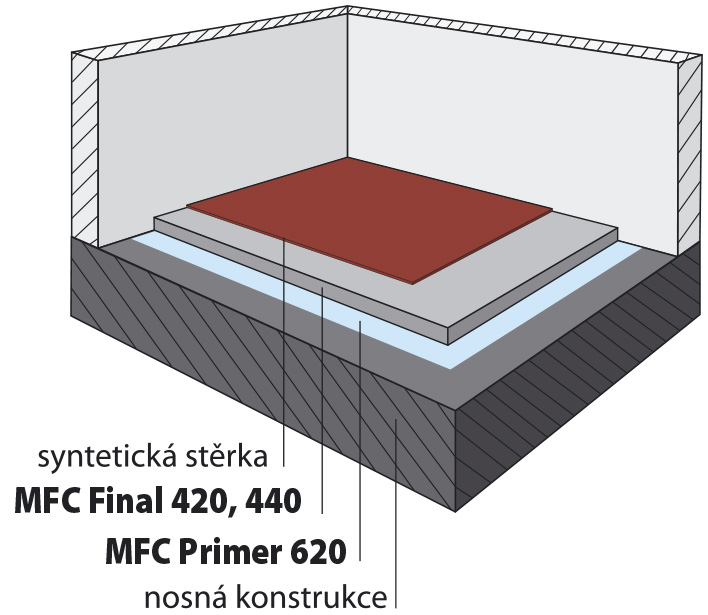

At present, one of the most progressive methods of surface treatment of concrete floors is the application of a layer of 4-15 mm high quality self-levelling screed to the surface of a mature, statically and dynamically stable concrete slab. The result is a colour-uniform surface with a high level of flatness and resistance to rolling loads. The system is very suitable both for new buildings and for the reconstruction of already inadequate floor areas.

System benefits:

- Productivity (cca 1000 m2 floor areas per day)

- High rolling resistance (RWA, BCA method)

- Color coherence

- Color options

- Surface without capillary cracks

- No need for dilation

- High level of flatness ± 1mm/2m of lath

- Wear layer in 3 hrs., fully operational at 7 days

- Long lifetime - min. 10 years

Materials used

Penetration: acrylic dispersion or epoxy resin based product. It is designed to seal and strengthen concrete, wood, ceramics, etc., or as a bridge between individual MFC levelling layers. They prevent leakage of water from the applied material into the substrate.

Self-levelling industrial screeds: is a self-levelling screed compound based on cement, filler, and special additives. It is supplied as a pre-mixed dry mixture that is mixed with water in the building. It is designed for industrial floors for both new and old concrete as a finishing finish. Individual products differ mainly in the type of abrasion resistant aggregate (silicon, corundum, corundum/carbide, carbide).

Impregnation: a preparation based on water-soluble epoxide, acrylate, or polyurethane. On the surface, it creates a thin, highly tough film that reduces natural water absorption, strengthens the surface and simplifies maintenance and surface cleaning. Resistant to water and detergent solutions.

| Materials used: | |||||

|---|---|---|---|---|---|

| Improvement of the substrate | MFC Sanfix 230 |

MFC Final 420 |

|||

| Penetration of the substrate | MFC Primer 620 | MFC Ekopox 660 | MFC Ekopox 661 | ||

| Self-levelling industrial screed | MFC Final 410 | MFC Final 411 | MFC Final 412 | MFC Final 413 | MFC Final 430 |

| Impregnations and coatings | MFC Ekopox 630 | MFC Ekopox 640 | MC DUR 2095 M | MFC Stoplak 610 | |

MFC compositions for industrial floor renovation

|

|

|