MFC System of the floors from brushed Micro Terrazo and Terrazzo CP

- Easy workability

- No volume changes

- Variability

- Lifetime

The system of decorative floors finds its wide application in civil and apartment construction, but also in industrial plants with aesthetic requirements or in redevelopment works on stair steps and corridors. This decorative technology offers aesthetic and highly durable solutions for commercial and administrative areas. The various filler sizes and colour of the bond matrix offer endless creative possibilities that can support the dominance and appearance of the final floor. Floors made of ground terrazzo can be applied to a variety of substrates, new machine-glazed concrete floors, aged concrete, weathered and otherwise damaged concrete surfaces, old paints, ceramic and terrazzo tiles.

For each of the given types of operations and due to the desired physical, chemical and aesthetic properties, different pieces of decorative flooring systems are chosen - self-levelling screeds MFC Micro Terrazzo or MFC Terrazzo CP matrix for the production of cast terrazzo, where both the colour of the matrix and the marble filler of different colours and fractions can be combined. Their colour design offers a wide range of combinations used for decorative floors not only in industry, but also in interiors

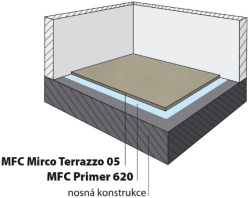

MFC Micro Terrazzo

is a self-levelling quick-drying screed compound based on cement, filler and special additives. It is designed for the preparation of highly aesthetic interior floor surfaces, followed by grinding and polishing. It is suitable for pedestrian-friendly spaces such as schools, department stores, offices, family houses etc. MFC Micro Terrazzo is suitable for finishing new and old concrete surfaces. MFC Micro Terrazzo is applied at a thickness of 8-30 mm. It is supplied in two basic colour variants - grey and white cement, additional colour shades can be prepared according to customer requirements by adding pigments.

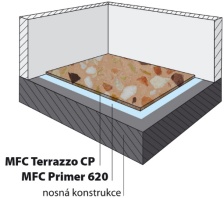

MFC Terrazzo CP

is a special fast-setting mixture based on cement and special additives. It is supplied as a pre-mixed dry mixture that is mixed with water and decorative filler on the building. It is designed as a binder for the production of terrazzo floors, followed by grinding and polishing. Cast terrazzo is applied in a 15-40 mm thickness by using aggregates (crushes) of sizes from 3 to 27 mm.

When using aggregates from 12 to 27 mm fractions, the casting height is individually adjusted. It is supplied in two basic colour variants - grey or white cement, other colour shades can be prepared according to customer requirements by adding pigments.

Penetration: The MFC Primer 620 penetration primer is applied by brush or sprayer to the cleaned substrate in a ratio of 1: 5 with first coat and 1: 3 with second coat. It is applied once or twice depending on the absorbency of the substrate. For less stable or highly absorbent substrates, it is recommended to use Ekopox 661 MFC epoxy penetration with subsequent quenching of silica sand.

Impregnation:

It is necessary to choose the correct surface impregnation according to the requirements of the given operation, for example:

Polymeric waxes – standard penetration and impregnation in final silk or high gloss.

Stone chemistry – used in high-stressed corridors, outdoor passages, retail spaces and in rooms where water is more common. In use, it is necessary to have a perfectly dry substrate, and it takes longer to dry and ventilate. The product is semi-glossy or matt.

System benefits:

- Layer thickness from 8 mm

- Easy workability

- No volume changes

- Wear layer in 3 hrs.

- surface sandable in 2-3 days

- Colour option

- Variability of solutions according to the kind of the filler used (stone, glass, metal etc.).

- Suitable for damp areas (e.g. garages, bathrooms, kitchens, etc.)

- Long lifetime - min. 10 years

Materials used

| Materials used: | |||||

|---|---|---|---|---|---|

| Improvements | MFC Sanfix 210 | MFC Sanfix 220 | MFC Sanfix 230 | MFC Sanfix 270 | |

| Penetration | MFC Primer 620 | MFC Ekopox 660 | MFC Ekopox 661 | ||

| Terrazzo | Micro Terrazzo 025 | Terrazzo CP Grey |

Terrazzo CP White |

||

| Impregnation | MFC Ekopox 630 | MFC Stoplak 610 | MC DUR 2095 M | ||

MFC compositions for industrial floor renovation

|

|