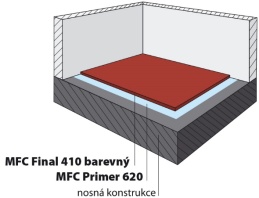

MFC System of decorative floors made of coloured thin-layer screeds

- Resistance

- Productivity

- Colour option

- High flatness

The system of decorative floors finds its wide application in civil and apartment construction, but also in industrial plants with aesthetic requirements. This decorative technology offers aesthetic and highly durable solutions for commercial and administrative areas. Combination of colour thin-layer screeds offers endless creative possibilities that can support the dominance and appearance of the final floor.

Floors of coloured screeds can be applied to a variety of substrates, new and old concrete floors, mature concrete, weathered and otherwise damaged concrete surfaces.

For each of the given types of operations and due to the desired physical, chemical and aesthetic properties, different pieces of decorative floor systems are selected. Their colour design offers a wide range of combinations used for decorative floors not only in industry but also in interiors.

Penetration: concentrated water-dilutable solution based on acrylate dispersion. It is designed to seal and strengthen concrete, wood, ceramics, etc., or as a bridge between individual MFC levelling layers. Prevents leakage of water from the deposited material into the substrate.

Self-levelling industrial screed: MFC Final 410 is a self-levelling screed based on cement, filler and special additives. It is supplied as a pre-mixed dry mixture, which is mixed with water in the building. It is designed for industrial floors for both new and old concrete as a final surface treatment. Individual products for decorative purposes differ in the colour used. The pot is supplied in eight basic colour variants: natural, grey, white, black, yellow, red, green and blue in different shades as required by the customer.

Impregnation: liquid preparation based on water-soluble epoxy or acrylate. On the surface it creates a thin, highly tough film that reduces natural water absorption and strengthens the surface. Resistant to water and detergent solutions.

System benefits:

- Layer thickness from 15 mm

- Easy workability

- Without volume changes

- Wear layer in 3 hrs.

- Surface sandable in 2-3 days

- Color option

- Variability of solutions according to the kind of the filler used (stone, glass, metal etc.).

- Suitable for damp areas (e.g. garages, bathrooms, kitchens, etc.)

- Long lifetime - min. 10 years

Materials used

| Materials used: | |||||

|---|---|---|---|---|---|

| Improvements | MFC Sanfix 210 | MFC Sanfix 220 | MFC Sanfix 230 | MFC Sanfix 270 | |

| Penetration | MFC Primer 620 | MFC Ekopox 660 | MFC Ekopox 661 | ||

| Polymer cement screeds | MFC Final 410 grey | MFC Final 410 black | MFC Final 410 red | MFC Final 410 yellow | MFC Final 410 green |

| MFC Final 410 blue | MFC Final 410 white | ||||

| Impregnation | MFC Ekopox 630 | MFC Ekopox 640 | MC DUR 2095 M | ||

MFC compositions for industrial floor renovation

|