MFC "dry to wet" (mineral fillings)

- Using mechanisation

- High productivity

- Low purchase price

- Colour options

This is a basic way of improving the surface of industrial concrete floors, which consists in applying 3 to 5 kg / m2 of the bulk material to the surface of the solid, pre-levelled and compacted concrete mixture. Subsequently, the surface is smooth with rotary trowels according to the gradual hardening of the concrete to the required quality. The result is a monolithic floor structure with an abrasion-resistant and dust-free surface at a layer thickness of about 2-3 mm.

System benefits:

- Using mechanisation

- High productivity (500 - 5000 m2 floor areas per day)

- High resistance to abrasion (BCA, Böhme method)

- Colour options

- Low purchase price

Materials used

Pour-ins: cement-based mixture, filler and special additives. It is supplied as a ready-to-use wet dry mixture to "dry-to-wet" system. Individual products differ primarily in the type of abrasion-resistant aggregate (silicon, metal, corundum, carbide).

Impregnations: liquid preparations that are applied shortly after surface finishing is completed. They are designed as a protective spraying or coating to prevent the evaporation of water from the concrete, thus effectively minimizing plastic deformations and increasing the hydration degree for about 3-4 weeks.

| Materials used: | |||||

|---|---|---|---|---|---|

| Pour-ins | MFC Cobet 110 | MFC Cobet 115 | MFC Cobet 120 | MFC Cobet 130 | MFC Cobet 140 |

| Impregnation | MFC Stoplak 610 | MFC Curol SiT 60 | |||

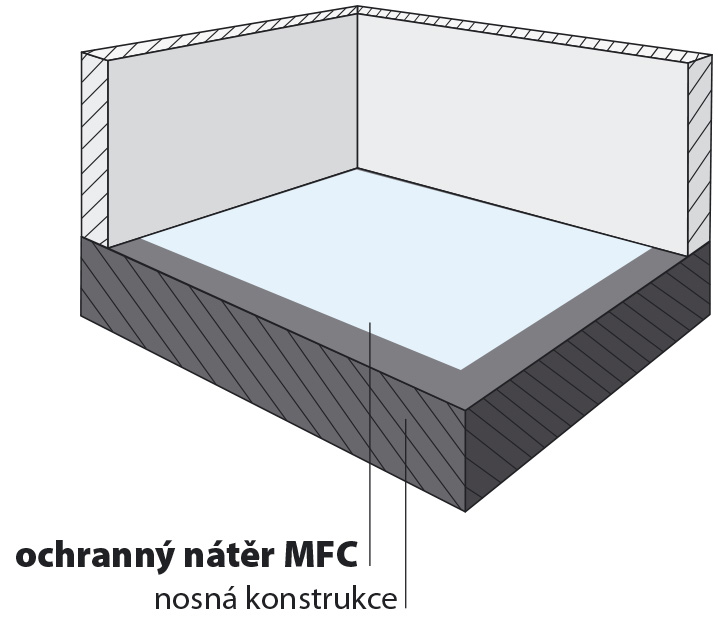

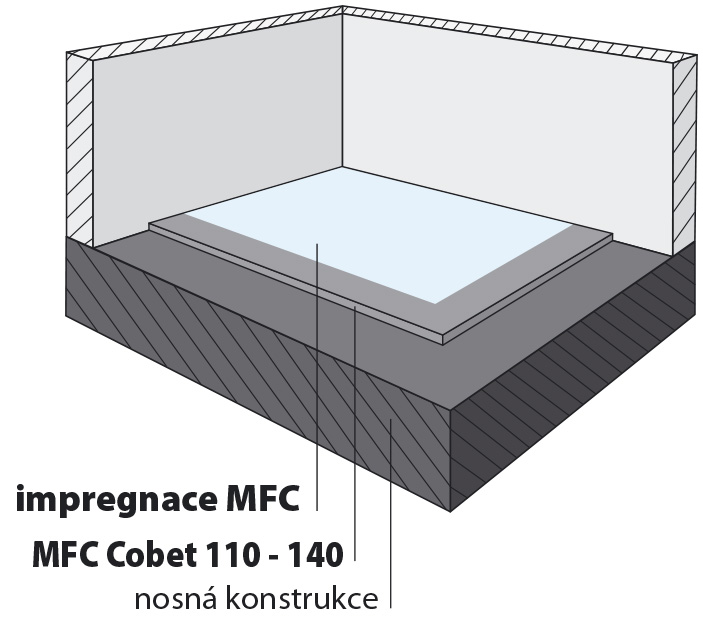

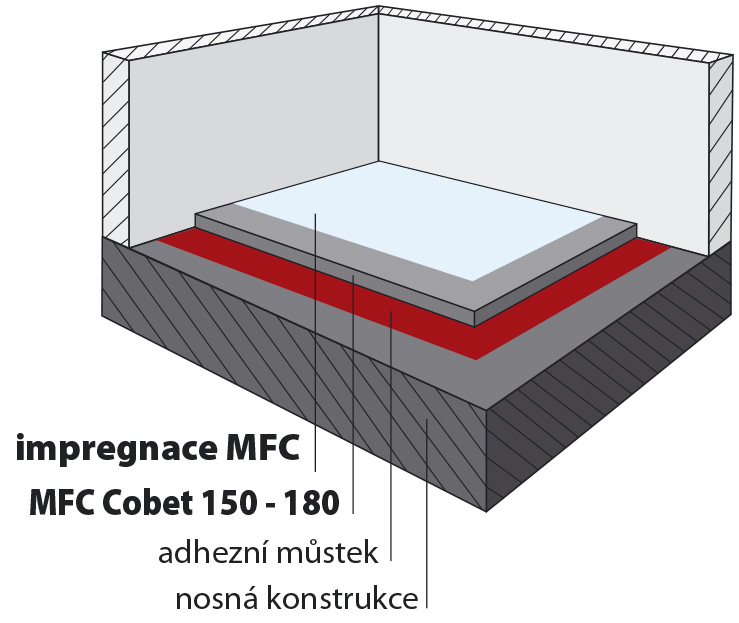

Compositions:

|

|

|

Usage

These materials are designed for surface treatment of fresh concrete floors in civic and industrial buildings. They improve surface processing, flatness, and resistance of the surface to mechanical loads.