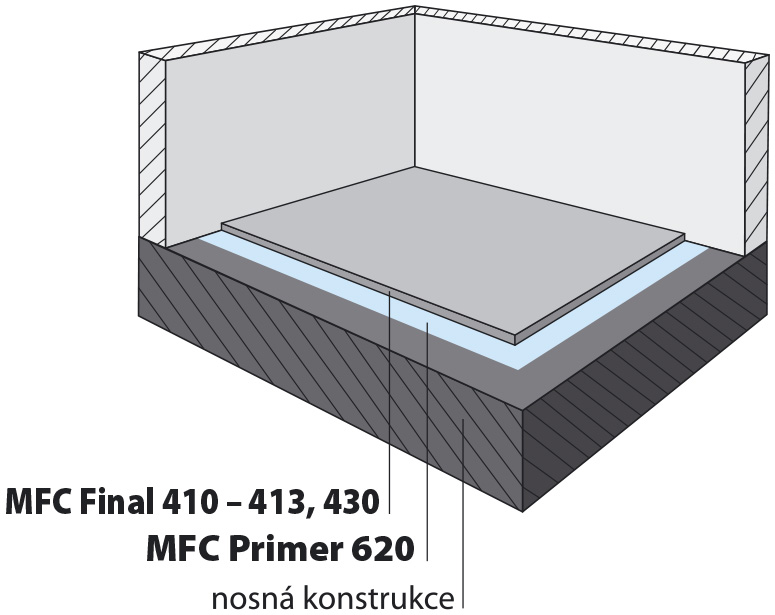

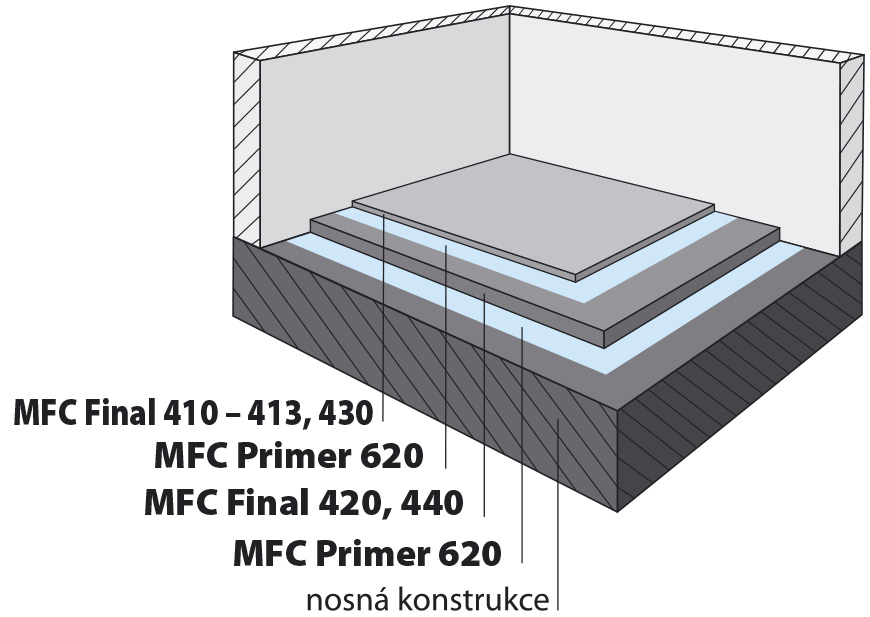

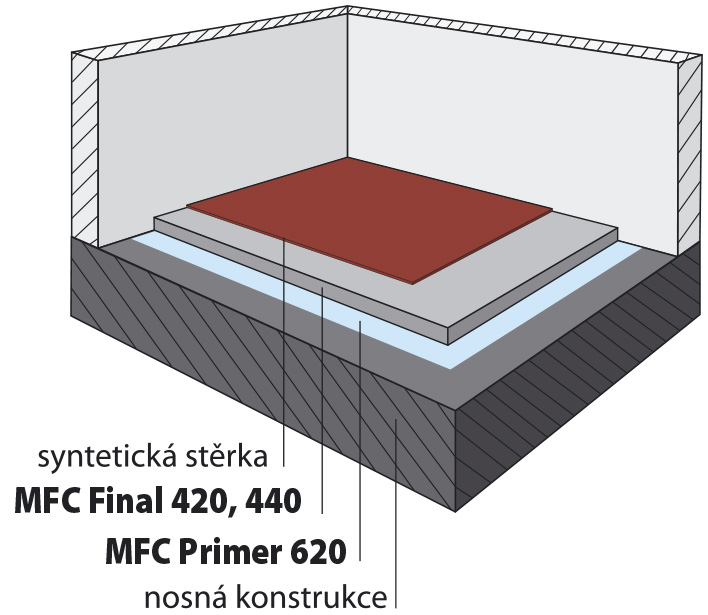

Currently, one of the most progressive ways of repairing concrete floors. It consists in applying a layer of 4-15 mm high quality self-levelling screed to the surface of a mature, statically and dynamically stable concrete slab. The result is a colour-uniform surface with a high level of flatness and resistance to rolling loads. The system is suitable both for new buildings and for the reconstruction of already unsuitable floor surfaces.

Materials used

Penetration: acrylic dispersion or epoxy resin based product. It is designed to seal and strengthen concrete, wood, ceramics, etc., or as a bridge between individual MFC levelling layers. They prevent leakage of water from the applied material into the substrate.

Self-levelling industrial screeds: is a self-levelling screed compound based on cement, filler and special additives. It is supplied as a pre-mixed dry mixture that is mixed with water in the building. It is designed for industrial floors for both new and old concrete as a finishing finish. Individual products differ mainly in the type of abrasion resistant aggregate (silicon, corundum, corundum / carbide, carbide).

Impregnation: a preparation based on water-soluble epoxide, acrylate or polyurethane. On the surface it creates a thin, highly tough film that reduces natural water absorption, strengthens the surface and simplifies maintenance and surface cleaning. Resistant to water and detergent solutions.

Materials are used for repairs of local chuck holes and cuts on floors, stairs, walls, corners, etc. (binders) or as a protective, filling or final layer of damaged concrete constructions (mortars).