Painting materials

Surface treatment of concrete and self-levelling screeds involves the use of systems designed to prepare substrates prior to application of additional layers or as a final coating. The materials differ in thickness of the applied layer, water and chemical resistance, mechanical and weather influences. With the appropriate choice of protection and coating system, the required properties can be obtained to extend the floor lifetime

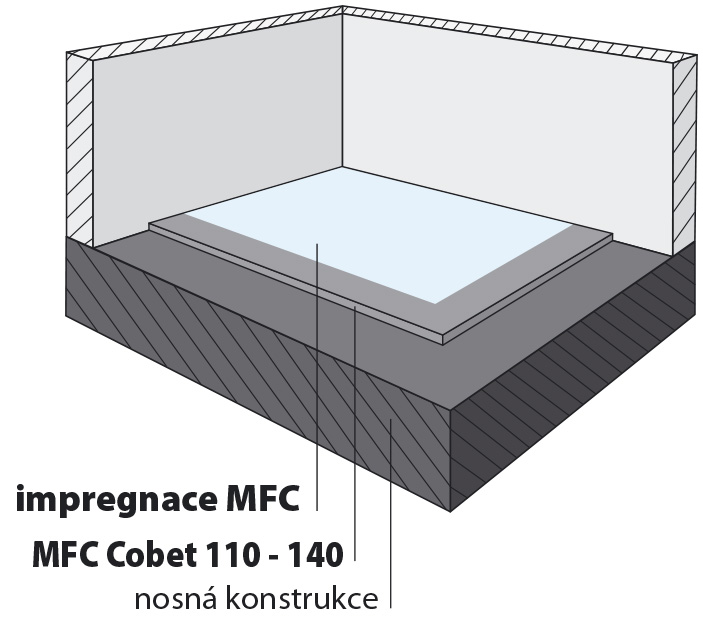

Impregnation: Used to modify concrete in order to reduce its surface porosity and to strengthen the surface. The pores and capillaries are partially or completely filled. This type of treatment also produces a discontinuous film of the thickness of 10-100 microns on the surface. This film serves to stop the penetration of aggressive substances into the pore system. Certain impregnations can react with some of the concrete components to provide more resistance to abrasion and mechanical attack.

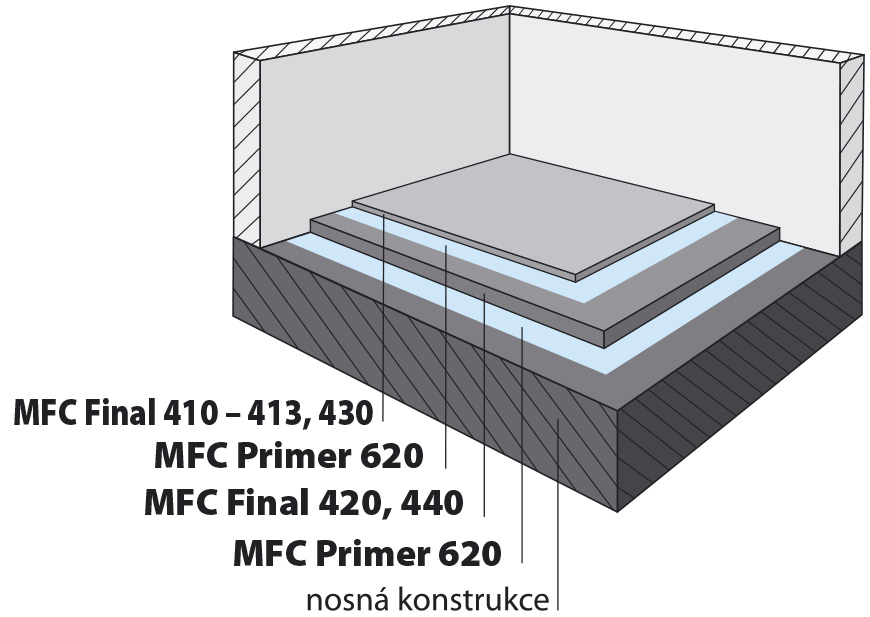

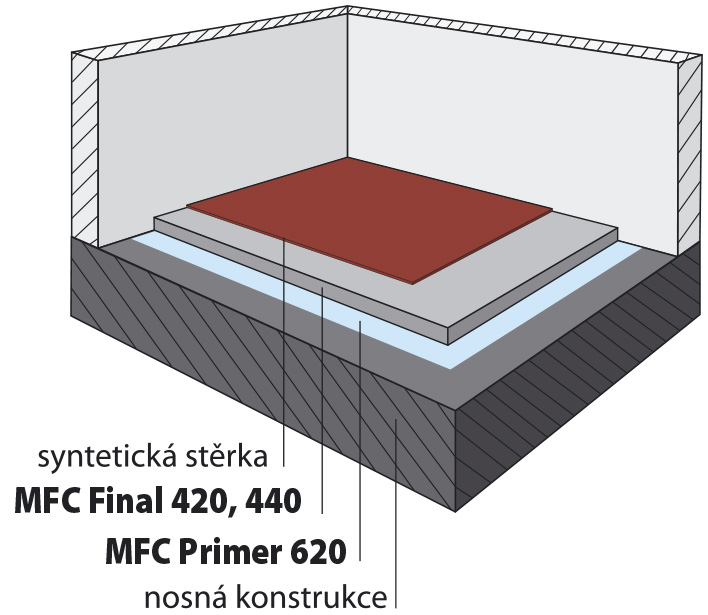

Penetration: serves to strengthen the substrate, anchor the dust particles, displace the air from the pores, reduce its absorbency and increase the adhesion of the surface for further treatment. The main purpose of penetration is not the protection of the material, but mainly the preparation of the substrate for the additional layers applied and the creation of a quality adhesive bridge.

Coating: it serves as a surface treatment that forms a continuous protective layer on the surface of the concrete or screed. Coatings are used to improve the quality of the concrete surface, to increase mechanical and chemical resistance or behaviour towards particular external influences. Last but not least, they provide aesthetic features and easy floor maintenance.

System benefits:

- Speed of repair

- Variability of materials

- Surface without capillary cracks

- No need for dilation

- Wear layer in 24 hours, 50% of the load after 7 days

- Long lifetime - min. 10 years

Materials used

| Materials used: | ||||

|---|---|---|---|---|

| Impregnation | MFC Stoplak 610 | MFC Ekopox 630 | MFC Ekopox 631 | MFC Curol SiT60 |

| Penetration | MFC Primer 620 | MFC Ekopox 660 | MFC Ekopox 661 | |

| Coatings | MFC Ekopox 640 | |||

| Special | MFC Ekopox 670 |

|||

Compositions

|

|

|